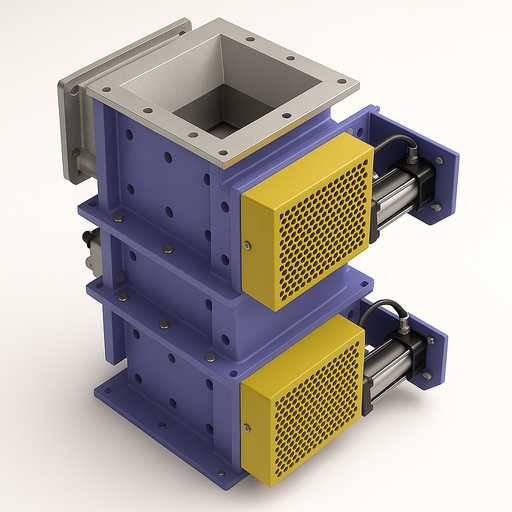

Double Flap Dump Valve

Experience our full-service capabilities designed to enhance efficiency, reliability, and performance.

Overview

Optimak’s Double Flap Dump Valves are engineered for handling abrasive, high-temperature, and fine powder materials in demanding bulk material handling applications. Designed to maintain a reliable airlock, they offer an effective alternative to rotary airlock valves, particularly where rotary wear is a concern.

Double Flap Dump Valves are ideal for providing a pressure-tight seal while allowing continuous or batch-wise discharge of bulk solids without compromising process integrity.

Key Features

Dual Gate Design: Two sequential flaps minimize air or gas leakage during material transfer.

Airlock Functionality: Maintains system pressure while discharging bulk materials.

Handles High Temperatures: Suitable for use in high-temperature environments.

Abrasive Material Compatibility: Designed for coarse, dusty, or abrasive bulk solids.

Low Maintenance: Simple mechanism with fewer moving parts reduces wear and servicing needs.

Customizable Build: Available in a range of sizes and materials including stainless steel and wear-resistant alloys.

Intermittent Discharge: Ideal for batch processes where continuous flow isn’t required.

Dust-Tight Operation: Enhances environmental control and reduces dust emissions.

Have specific material or pressure requirements?

Talk to our engineering team to design a Double Flap Dump Valve that fits your exact process needs.