Industrial Valves

At Optimak, we engineer high-performance valves designed to manage the controlled flow of bulk materials in industrial processes. Whether it’s isolating, diverting, or regulating materials, our valves ensure safety, accuracy, and durability in demanding environments.

Explore our range of industrial-grade valves:

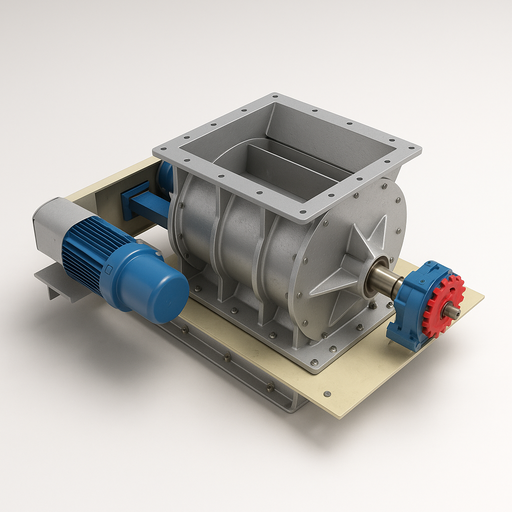

Rotary Air Lock Valves are essential for discharging bulk materials from hoppers or dust collectors while maintaining airlock conditions. Optimak’s design offers precision, minimal air leakage, and robust construction—ideal for pneumatic conveying systems and dust control setups.

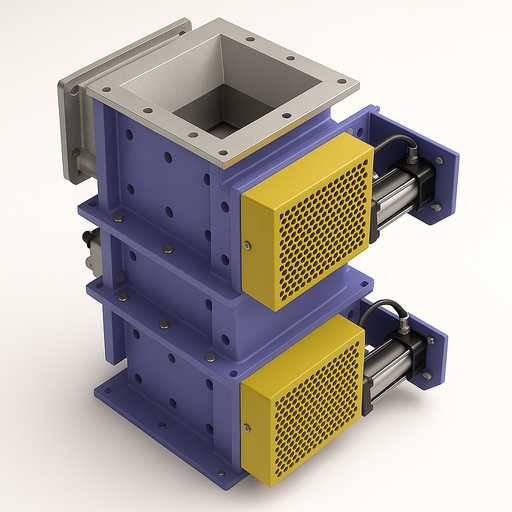

Double Flap Dump Valves provide air-tight sealing for high-temperature and abrasive materials. With two synchronized flaps operating alternately, they ensure continuous discharge without air seepage—making them perfect for cyclone discharge, bag filters, and kiln feed points.

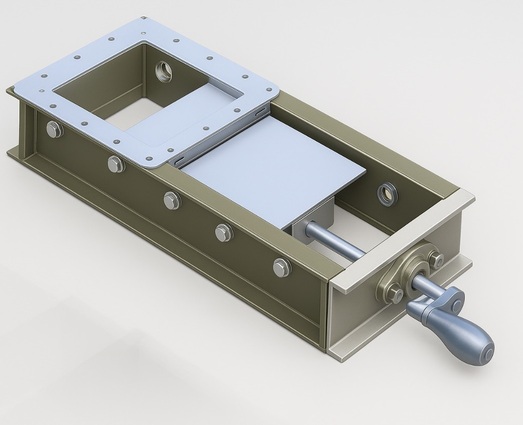

Slidegate Valves are used to control the flow of dry bulk materials. Optimak’s slidegates feature heavy-duty construction with tight shutoff, suitable for silos, hoppers, and conveyor discharge points. Available in manual, pneumatic, or motorized options.

Diverter Valves route material flow from one source to multiple destinations. Our rugged diverters are designed to handle abrasive powders and granules while minimizing flow obstruction and wear—ideal for pneumatic conveying and gravity flow systems.

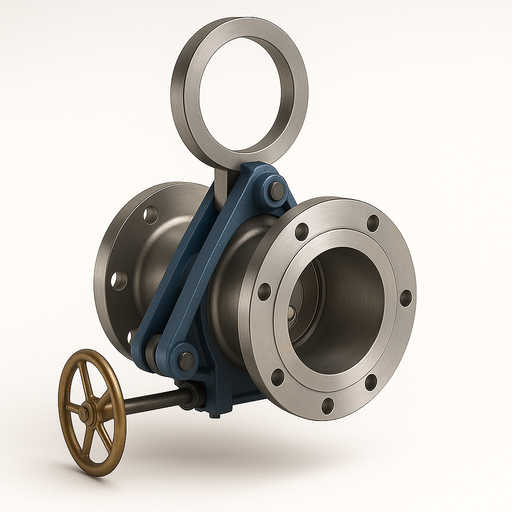

Spectacle Blind Valves are used for positive isolation during maintenance or process shut-off. Optimak’s design offers quick switching between flow and blank-off positions, ensuring operational safety in pipelines handling gases, powders, or fluids.

Need Help Choosing the Right Valve?

Our engineering team can recommend or customize the perfect valve solution for your process.